2025 marks a pivotal year for the sheet metal fabrication industry, driven by rapid adoption of automation, AI, and advanced manufacturing technologies. The global market is projected to reach $15.2 billion by 2034, with a strong 4.0% CAGR, fueled by demand in automotive, aerospace, and construction. Industry leaders now prioritize Innovations in Sheet Metal Fabrication Technology, such as collaborative robotics, digital transformation, and sustainable practices, to increase efficiency, precision, and competitiveness.

Manufacturers see significant gains from automation and AI-powered quality control, with over 54% of facilities worldwide integrating these systems. The shift toward on-demand manufacturing and advanced materials signals a new era, offering practical opportunities for businesses to boost productivity, reduce waste, and lead in a changing marketplace.

Automation Advances

Automation innovations continue to reshape sheet metal fabrication in 2025. Companies invest in advanced robotics and smart systems to address labor shortages, improve safety, and boost productivity. The adoption of robotic welding and automated material handling has reached new heights, especially in North America and the automotive sector.

Robotic Welding

Safety and Productivity

Robotic welding systems now dominate large-scale manufacturing. These robots handle repetitive and hazardous tasks, reducing workplace accidents by 50%. Many facilities report a 30% drop in defect rates for aerospace components and a 40% increase in production speed after implementing robotic welding. Companies also see a 25% reduction in labor costs and a 15% decrease in material waste. These improvements allow operators to focus on quality control and higher-value work.

Aspect | Data / Statistic |

Adoption of Collaborative Robots | 63% of sheet metal processing units integrate cobots |

Welding Robots Share | 38% of total metal manufacturing robot installations |

Robotic Welding Adoption | 68% in large-scale manufacturers; 52% increase in robotic arc welding applications |

Regional Adoption - North America | 72% of metalworking facilities use robotic arms for welding and material handling |

Market Growth | Robotic welding market expected CAGR of 10.6% driven by Industry 4.0, labor shortages, cost pressures |

Robotic welding technology now includes spot welding, laser welding, and multi-axis positioning. Lightweight collaborative robots (cobots) can be deployed directly at the workpiece, increasing flexibility. AI-powered systems generate welding paths, monitor welds in real time, and adjust parameters automatically. These features ensure consistent quality and reduce setup times.

Flexible Deployment

Manufacturers value the flexibility of modern robotic welding. Cobots with magnetic bases or pallets move easily between workstations. Multi-axis systems weld complex parts with precise alignment. Companies use these robots for spot welding panels, laser welding architectural metalwork, and even retrofitting older equipment. This flexibility supports rapid changes in production and meets diverse customer needs.

Note: The automotive sector leads in robotic welding adoption, using spot and arc welding robots for chassis and body panels. The electrical and electronics industry follows closely, driven by the need for precision welding.

Material Handling Automation

Error Reduction

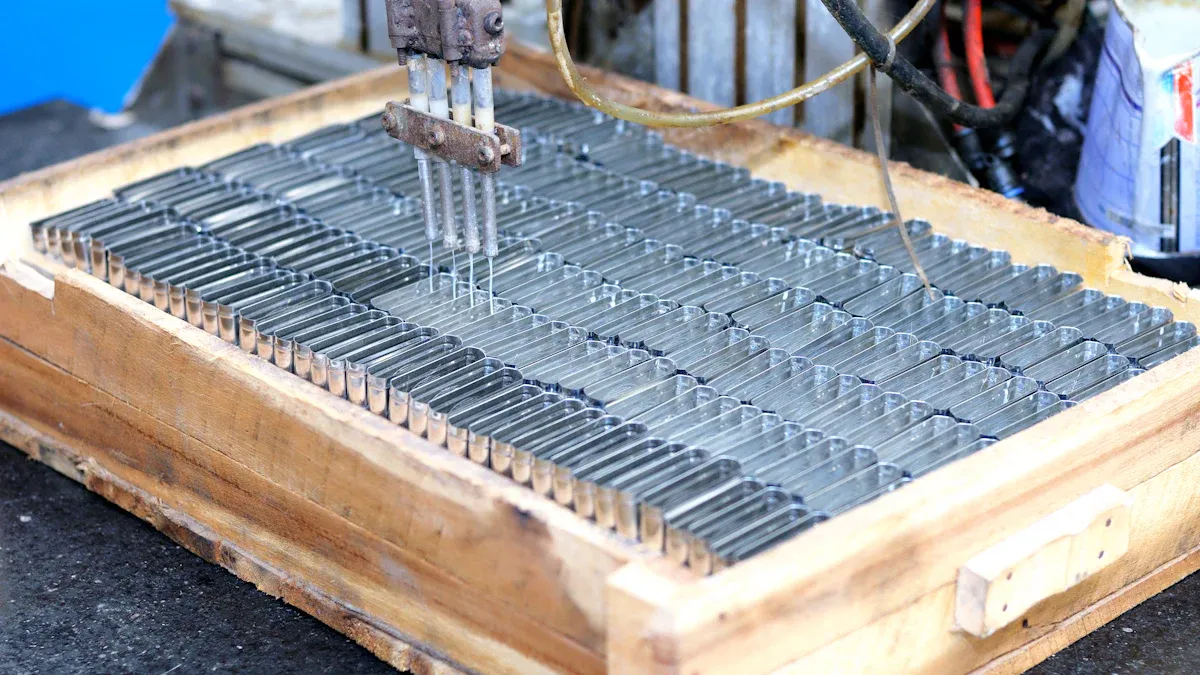

Material handling automation eliminates repetitive manual tasks and reduces human error. Robots perform pick-and-place operations, improving process reliability and worker safety. Facilities report fewer repetitive motion injuries and a significant drop in errors. Automated lines produce up to 1,000 enclosures over two shifts, with a new enclosure emerging every 40 seconds. Laser welding and robotic handling ensure precise welds, reducing the need for post-weld grinding or polishing.

Automation improved operational efficiency by 52% and reduced worker fatigue by 33%.

Automated machines like panel benders perform complex tasks with perfect precision.

Real-time data monitoring identifies bottlenecks, improving efficiency by 10%.

Smart Factory Integration

Enhanced automation supports smart factory integration. Industry 4.0 technologies, such as AI and IIoT, simplify programming and scheduling. Machines self-set up and handle materials, allowing operators to focus on higher-value tasks. This approach increases scalability and flexibility, enabling businesses to grow without proportional increases in labor costs. North America leads in adoption, with 72% of facilities using robotic arms for welding and material handling.

Companies that embrace automation innovations position themselves for long-term success in a competitive market.

AI and Digitalization

Artificial intelligence and digitalization now drive the next wave of transformation in sheet metal fabrication. Companies use these technologies to achieve higher quality, efficiency, and adaptability. In 2025, AI-powered quality control and process optimization stand out as the most influential trends.

AI Quality Control

Defect Detection

AI-powered vision systems have revolutionized defect detection in sheet metal fabrication. These systems inspect parts faster and more accurately than human inspectors. Advanced robotic welding systems with AI vision sensors can detect welding defects as small as 0.3 mm, achieving over 80% accuracy. Real-time quality inspections allow manufacturers to catch issues early, reducing costly rework and scrap. For example, Company Y implemented AI vision technology and cut scrap rates by 50%, while also improving product quality. Human expertise remains essential, as skilled operators work alongside AI to drive innovation and ensure the best outcomes.

Data-Driven Improvements

AI algorithms analyze production data to identify trends and predict potential problems. This data-driven approach enables continuous improvement in quality control. Digital twins simulate fabrication processes, helping engineers spot defects before production begins. By combining physics-based and data-driven AI methods, manufacturers optimize part performance and quality. Companies that use AI-driven computer vision systems can make real-time adjustments, further reducing errors and boosting efficiency.

Tip: Integrating AI with human oversight creates a powerful hybrid system that maximizes both speed and accuracy in quality control.

Process Optimization

Predictive Maintenance

Process optimization relies heavily on predictive maintenance powered by AI in automation. AI analyzes historical and real-time data from machines to forecast equipment failures. This proactive approach reduces downtime and repair costs. Company X adopted AI predictive maintenance and saw a 30% drop in equipment downtime, along with a 20% increase in productivity. Digital twins provide real-time monitoring of equipment performance, allowing immediate detection of anomalies and scheduling of maintenance before breakdowns occur.

Adaptive Workflows

Digital twins and real-time monitoring tools enable adaptive workflows. These technologies create virtual replicas of physical processes, updated continuously with live data. Manufacturers use this information to identify inefficiencies, optimize resource allocation, and fine-tune machine operations. Simulation engines within digital twins allow scenario planning, helping teams make proactive adjustments to improve throughput and reduce waste. Visualization tools, such as multi-trend displays, provide actionable insights for precise equipment monitoring and strategic planning.

Digital twins support remote operations, increasing flexibility and responsiveness.

AI-driven systems enhance sustainability by optimizing energy use and minimizing environmental impact.

Manufacturers who embrace AI and digitalization position themselves at the forefront of innovation, ready to meet the demands of a rapidly evolving industry.

Innovations in Sheet Metal Fabrication Technology

Innovations in sheet metal fabrication technology continue to redefine industry standards in 2025. Manufacturers now rely on advanced laser cutting and CNC rolling systems to achieve higher speed, accuracy, and versatility. These technologies support the growing demand for complex designs and efficient production.

Fiber Laser Cutting

Speed and Precision

Fiber laser cutting stands out as a major advancement in innovations in sheet metal fabrication technology. Modern fiber lasers cut sheet metal at speeds up to 866 inches per minute, far surpassing older CO2 lasers. This rapid processing enables manufacturers to handle large volumes without sacrificing quality. Multi-axis laser cutting machines deliver intricate features, such as holes, contours, and threads, with minimal heat distortion. Intelligent laser movement ensures sharp, crisp edges, virtually eliminating the need for secondary deburring. Monitoring systems detect machining errors in real time, reducing rework and maintaining tight tolerances.

Advancement Aspect | Description |

Cutting Speed | Up to 866 inches per minute, much faster than CO2 lasers |

Edge Quality | Sharp, precise cuts with minimal need for finishing |

Monitoring & Precision | Real-time error detection and reduced rework |

Operational Cost & Energy | Lower energy use and maintenance, halving operational costs |

Industry 4.0 Integration | Supports AI, IoT, and remote monitoring for enhanced efficiency |

Fiber laser cutting also reduces operational costs and environmental impact. The solid-state design lowers maintenance needs and increases machine uptime. Manufacturers benefit from long-term cost savings and improved sustainability.

Versatility

Fiber laser cutting offers unmatched versatility in innovations in sheet metal fabrication technology. These systems process a wide range of metals, including steel, copper, and brass, as well as thicker materials—up to half an inch for stainless steel and aluminum. Automation features, such as automatic nozzle changers and part sorting robots, minimize manual intervention. This flexibility allows manufacturers to switch between jobs quickly and meet diverse customer requirements. Industries like automotive, aerospace, and electronics use fiber lasers for both precision and complex designs.

Fiber lasers enable fabrication of intricate features without heat distortion.

Automation and AI integration support remote monitoring and adaptive beam control.

Hybrid systems combine laser cutting with other processes for greater efficiency.

CNC Sheet and Plate Rolling

Multi-Axis Machining

CNC sheet and plate rolling machines represent another leap in innovations in sheet metal fabrication technology. Automated roll adjustment systems provide precise control over roll gap and position, reducing setup time and increasing production efficiency. Dynamic crowning systems maintain optimal pressure distribution, ensuring consistent bending even for complex shapes. CNC integration allows for multi-axis machining, enabling the creation of non-standard geometries and tight tolerances.

Intelligent controls use advanced algorithms for smooth transitions between different radii.

Four-roll CNC machines maintain constant reference points, reducing errors and improving repeatability.

Real-time measurement systems provide feedback for automatic adjustments, enhancing precision.

CAD/CAM Integration

CAD/CAM integration further enhances the capabilities of CNC rolling machines. Operators program machines directly from digital models, ensuring accurate reproduction of parts. The CNC control stores precise roll settings, allowing for consistent results across multiple production runs. Automation reduces manual intervention, speeds up production cycles, and enables less experienced operators to achieve reliable outcomes. Hybrid machines that combine press brake and plate rolling functions increase versatility and reduce the need for multiple setups.

Modern CNC rolling machines can integrate with robotic handling systems, boosting throughput and supporting smart factory initiatives.

Innovations in sheet metal fabrication technology, such as fiber laser cutting and CNC rolling, empower manufacturers to deliver high-quality, customized products at unprecedented speed and efficiency.

Custom Sheet Metal Fabrication

The landscape of custom sheet metal fabrication has changed dramatically in 2025. Digital technology now drives the shift toward on-demand production and highly tailored solutions. Companies that embrace these advancements gain a significant edge in speed, flexibility, and quality.

On-Demand Production

Fast Turnaround

On-demand production has become a cornerstone of custom sheet metal fabrication. Manufacturers leverage automated CNC machines, robotics, and advanced CAD software to deliver parts quickly. Automated laser and punching equipment enable rapid part production, often achieving turnaround times that were once impossible. Businesses can introduce new products to market faster, adapting to changing customer needs with minimal delay. This approach also allows companies to optimize efficiency and product quality without heavy investment in equipment.

Small Batch Flexibility

Custom sheet metal fabrication thrives on flexibility. On-demand services support low to medium production volumes, making them ideal for small batch runs and prototypes. Modern CNC machines achieve tolerances under 0.1mm, ensuring high-quality, repeatable results for every order. Companies benefit from cost-effective production, as they only manufacture what is needed, minimizing material waste through optimized cutting layouts. The process accommodates a wide range of metals, including steel, aluminum, titanium, and copper alloys, offering unmatched material versatility.

Businesses using contract manufacturing for custom sheet metal fabrication can focus on their core strengths while scaling operations efficiently.

Digital Manufacturing

Customization

Digital manufacturing has unlocked new levels of customization in custom sheet metal fabrication. Exception-based workflows allow CAD/CAM programmers to intervene only when necessary, streamlining the process and reducing manual programming. Laser cutting and robotic bending enable precise, complex shapes with minimal finishing, supporting intricate custom designs. Advanced CAD and nesting software automate design and material optimization, making it easy to produce unique parts for each customer.

Workflow Automation

Workflow automation stands at the heart of modern custom sheet metal fabrication. Real-time monitoring and analytics provide visibility into machine performance and production status. Integration with ERP and MRP systems creates a closed-loop production process, ensuring seamless communication across the shop floor. Smart machines and robotics automate repetitive tasks, improving efficiency and product quality. IoT connectivity and AI-driven analytics optimize processes, predict failures, and autonomously adjust parameters, reducing downtime and enhancing workflow continuity.

Unified digital platforms link sales, engineering, and manufacturing, eliminating communication barriers.

Standardized documentation and real-time validation prevent costly errors and delays.

Automation accelerates the journey from customer order to finished product, enabling higher customization with shorter lead times.

Custom sheet metal fabrication in 2025 stands as a model of efficiency, adaptability, and innovation. Companies that invest in digital tools and on-demand services position themselves to meet the demands of a rapidly evolving market.

Sheet Metal Fabrication Techniques

Modern sheet metal fabrication techniques have evolved rapidly in 2025, delivering higher quality and longer-lasting products. Manufacturers now rely on advanced forming and enhanced finishing to meet the demands of industries such as automotive, aerospace, and electronics.

Advanced Forming

High-Speed Stamping

High-speed stamping stands out as a core process in many production lines. This method uses automated presses to shape metal sheets at incredible speeds, producing thousands of parts per hour. Companies benefit from consistent part quality and reduced cycle times. High-speed stamping works well for both simple and complex geometries, making it a preferred choice for mass production.

Manufacturers also adopt several new forming methods to improve product quality:

Hydroforming uses high-pressure hydraulic fluid to create intricate shapes with excellent surface finish, ideal for aerospace applications.

Incremental sheet forming allows for complex shapes with lower tooling costs, supporting rapid prototyping.

Press hardening, or hot forming, heats steel to form strong, complex parts, especially for automotive safety components.

Flexforming uses hydraulic pressure and a flexible diaphragm to shape metal, offering versatility for custom parts.

CNC brake forming and servo-electric bending deliver precise, repeatable bends with energy efficiency and faster cycles.

Robotic automation ensures consistency and safety in bending and material handling.

Digital twin and simulation technologies enable virtual testing, optimizing tooling and reducing prototyping time.

Industry 4.0 smart manufacturing connects equipment for real-time quality monitoring and predictive maintenance.

Advanced materials, such as high-strength aluminum alloys, require specialized forming methods to maintain quality.

These innovations in sheet metal fabrication techniques help manufacturers achieve tighter tolerances and greater design flexibility.

Servo Presses

Servo presses have become essential in modern forming operations. They use programmable motors to control speed, force, and position with high accuracy. Operators can adjust press parameters for each job, ensuring optimal results for different materials and thicknesses. Servo presses also reduce noise and energy consumption, making them a sustainable choice for busy factories.

Enhanced Finishing

Surface Quality

Enhanced finishing methods play a vital role in improving the appearance and durability of sheet metal products. Techniques such as bead blasting remove imperfections and create uniform matte finishes. Chemical milling etches decorative patterns or logos onto surfaces, adding value for consumer products. Anodizing forms a protective oxide layer, improving both surface quality and corrosion resistance, especially for aluminum parts.

Corrosion Resistance

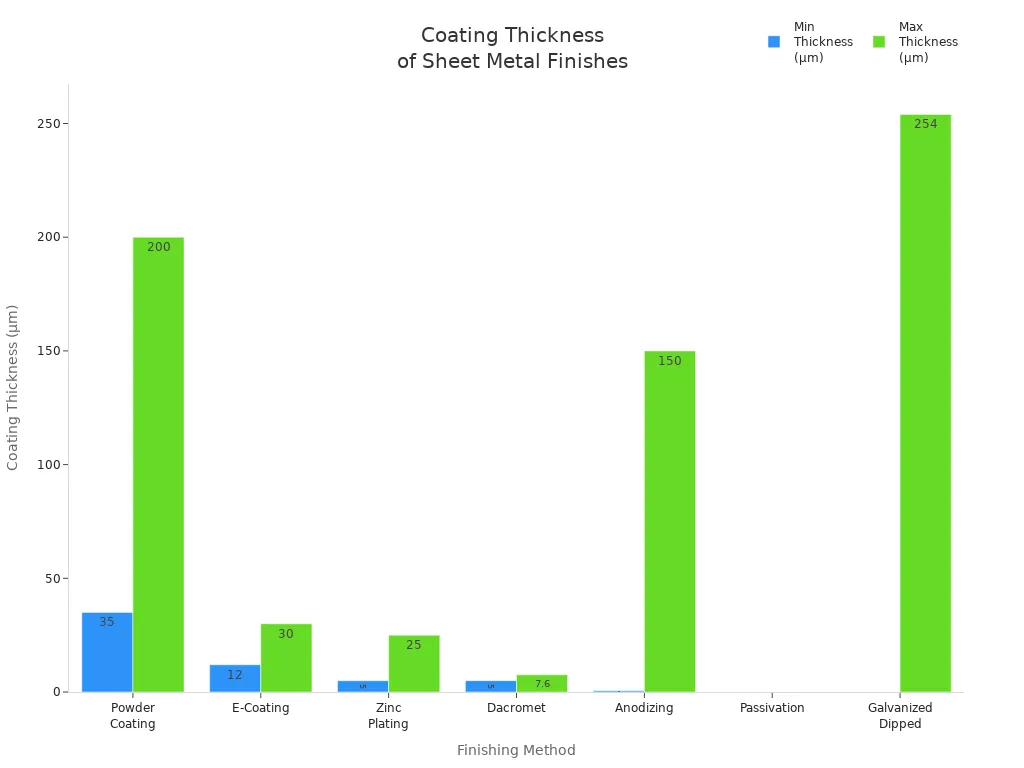

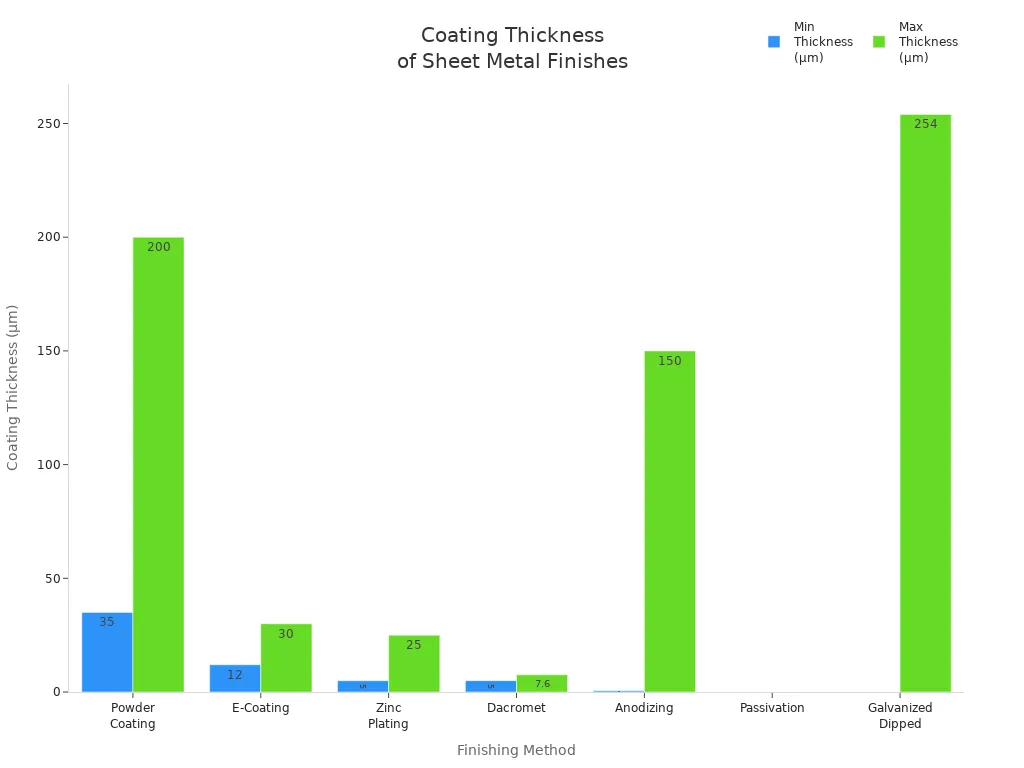

Corrosion resistance remains a top priority in sheet metal fabrication techniques. Manufacturers use a range of coatings and treatments to protect metal surfaces:

Finishing Method | Corrosion Resistance | Coating Thickness | Abrasion Resistance |

Powder Coating | Prevents water and corrosive substances from contacting metal | 35 to 200 µm | Hard, heat-cured finish with good abrasion resistance |

E-Coating | Forms a physical and chemical barrier | 12 to 30 µm | Durable, heat-cured finish |

Zinc Plating | Acts as a sacrificial anode for corrosion protection | 5 to 25 µm | Strong, highly durable finish |

Dacromet | Provides barrier and passivation effect | 5 to 7.6 µm | Chemically and heat resistant |

Anodizing | Excellent for marine environments | 0.5 to 150 µm | Hard, wear-resistant finish |

Passivation | Forms an inert oxide layer, removing free iron | Thin, transparent | Does not affect abrasion resistance |

Galvanized Dipped | Barrier resistance and sacrificial anode | Up to 254 µm | Good abrasion resistance and durability |

Powder coating and e-coating provide durable, colorful finishes that resist wear and corrosion. Zinc plating and galvanizing offer strong protection for outdoor and industrial applications. Anodizing and passivation enhance the longevity of aluminum and stainless steel components.

Tip: Selecting the right finishing method extends product life and reduces maintenance costs.

By combining advanced forming with enhanced finishing, manufacturers unlock new possibilities in sheet metal fabrication techniques. These improvements, along with high-speed cutting and smart automation, ensure products meet the highest standards for quality and durability.

Sustainability Trends

Sustainability has become a central focus in sheet metal fabrication in 2025. Companies now recognize that eco-friendly practices not only protect the environment but also drive operational efficiency and long-term profitability. The industry has shifted toward green manufacturing and robust waste reduction strategies, setting new standards for responsible production.

Green Manufacturing

Energy Efficiency

Manufacturers have made significant progress in energy efficiency. Many facilities now use electric arc furnaces (EAF) powered by renewable energy. These furnaces melt recycled scrap steel, reducing energy consumption and greenhouse gas emissions. Some companies have adopted green hydrogen as a fuel source, which produces only water vapor instead of carbon dioxide. This shift lowers the carbon footprint of sheet metal production.

Digital technologies play a key role in optimizing energy use. Smart sensors and AI-driven energy management systems monitor equipment in real time. These tools identify inefficiencies and help operators adjust processes to minimize waste. Predictive maintenance further reduces unnecessary energy use by ensuring machines run only when needed.

Companies that invest in energy-efficient technologies often see lower utility costs and improved ESG (Environmental, Social, and Governance) performance.

Renewable Integration

The integration of renewable energy sources has accelerated. Solar panels and wind turbines now supply a growing share of electricity for fabrication plants. Some manufacturers use blockchain technology to track renewable energy usage and ensure supply chain transparency. Internal carbon pricing encourages responsible sourcing and investment in clean energy projects.

Waste Reduction

Recycling

Recycling has become a cornerstone of sustainable sheet metal fabrication. Plants now use more recycled materials, especially scrap-based steel. This approach can cut energy consumption by up to 60% compared to processing virgin ore. Lean manufacturing principles help eliminate unnecessary steps and reduce material waste.

Many companies have replaced wooden pallets with LEAN Re-Rack cartridges. These cartridges securely house sheet metal, reducing damage and minimizing waste. The system also supports a 'milk run' process, which improves collaboration between suppliers and manufacturers and ensures consistent material quality.

Closed-Loop Systems

Closed-loop systems have transformed material handling and inventory management. LEAN Sheet Metal Storage Systems optimize the flow of materials from receipt to machine loading. These systems maximize floor space, streamline inventory, and reduce production downtime. By minimizing inbound shipments, companies lower fuel costs and carbon emissions.

LEAN cartridges and storage systems reduce lumber use and the carbon footprint of traditional logistics.

Automated tracking and real-time data help maintain high productivity while supporting sustainability goals.

Sustainability trends in 2025 highlight the industry's commitment to energy efficiency, renewable integration, recycling, and closed-loop systems. These practices not only protect the environment but also enhance competitiveness and operational excellence.

Advanced Materials

Lightweight Alloys

Aluminum-Lithium

Aluminum-lithium (Al-Li) alloys have become a game-changer in sheet metal fabrication. These alloys combine low density with high stiffness, making them ideal for aerospace and advanced transportation. Boeing plans to use Al-Li alloys for the fuselage of its 777-X aircraft, demonstrating the material’s growing role in aviation. Alcoa, now Arconic Inc, has invested in dedicated production facilities to meet the demand for aerospace-grade Al-Li alloys.

Al-Li alloys, such as the 2195 grade, offer high tensile strength (≥560 MPa in T8 temper), excellent fatigue resistance, and good ductility. The addition of lithium reduces density and increases stiffness, while elements like copper and magnesium enhance strength and corrosion resistance. These properties make Al-Li alloys attractive for both aerospace and military applications, where weight savings and durability are critical.

Aluminum-lithium alloys also support sustainability goals by reducing overall aircraft weight, which leads to lower fuel consumption and emissions.

Advanced Steels

Automotive and industrial sectors increasingly rely on advanced high-strength steels (AHSS) to achieve lighter, safer, and more efficient vehicles. Companies like Ford and General Motors use AHSS in structural components, reducing vehicle weight by up to 30% compared to traditional mild steel. This weight reduction improves fuel economy and enhances crash performance.

Chevy Colorado and Nissan Maxima use AHSS for critical structural parts.

New manufacturing methods, such as tailor rolling and optimized alloy placement, improve part performance and material efficiency.

Alcoa’s Micromill technology produces aluminum sheets that are 40% more formable and 30% stronger than standard alloys, with production times reduced from 20 days to just 20 minutes.

Automakers have also shifted to aluminum for body panels, as seen in Ford’s F-150, which achieved a 750-pound weight reduction. This transition required new alloy selection, heat treatments, and training for repair shops, highlighting the complexity of adopting advanced materials.

Smart Materials

Shape Memory Alloys

Shape memory alloys (SMAs), especially nickel-titanium (NiTi), introduce unique capabilities to sheet metal fabrication. These materials can return to a pre-set shape when exposed to heat or other stimuli. Additive manufacturing techniques, such as Selective Laser Melting (SLM) and Electron Beam Melting (EBM), enable the creation of complex SMA components that traditional forming cannot achieve.

SMAs find applications in aerospace for morphing wings and adaptive actuators, in biomedical devices for self-expanding stents, and in robotics for soft actuators. Their superelasticity and shape memory effect allow engineers to design adaptive parts that respond to environmental changes.

Adaptive Components

Adaptive components made from smart materials are transforming product design. Engineers use SMAs to create actuators and dampers that adjust automatically to temperature or stress. Additive manufacturing allows for greater customization and material efficiency, supporting the production of lightweight, functional parts.

While challenges remain—such as high material costs and processing complexity—collaboration with material scientists and process optimization can unlock the full potential of smart materials in sheet metal fabrication.

These advances in lightweight alloys and smart materials position manufacturers to deliver stronger, lighter, and more adaptive products, meeting the evolving demands of modern industries.

Smart Manufacturing

Smart manufacturing has become a defining feature of sheet metal fabrication in 2025. Companies now rely on digital connectivity and immersive technologies to drive efficiency, quality, and innovation. Two key pillars—IIoT integration and AR/VR applications—stand out as transformative forces.

IIoT Integration

Real-Time Data

Industrial Internet of Things (IIoT) integration has revolutionized data collection on the shop floor. Sensors embedded in machines and production lines connect with programmable logic controllers (PLCs), enabling real-time tracking of Overall Equipment Effectiveness (OEE). Operators receive immediate insights into equipment availability, performance, and quality. Automated Optical Inspection (AOI) and Computer Vision (CV) systems inspect parts as they move through production, catching defects early and improving traceability.

IIoT also enhances accountability. Systems use QR codes for bin, pallet, and part management, making it easy to track every component. This level of traceability supports quality assurance and regulatory compliance. By streamlining workflows, IIoT reduces manual intervention and eliminates bottlenecks. Departments communicate more effectively because integrated systems share data instantly.

IIoT networks enable continuous real-time data collection from diverse sensors and devices. This foundation supports advanced analytics and smarter decision-making across the factory.

Predictive Analytics

Predictive analytics powered by IIoT has changed how manufacturers approach maintenance and planning. Continuous equipment health monitoring allows teams to schedule maintenance based on actual performance data, not just fixed intervals. This approach reduces unexpected downtime and extends machine life.

Machine learning models, including deep reinforcement learning and ensemble techniques, analyze the vast data streams from IIoT devices. These models predict equipment failures before they happen, optimize maintenance schedules, and improve resource allocation. Advances in graph neural networks further enhance fault detection and resource management, even in complex and changing environments.

IIoT also supports predictive forecasting for demand planning, supply chain optimization, and capacity planning. Companies use these insights to stay competitive and responsive in a fast-moving market.

Key Benefits of IIoT Integration:

Real-time OEE tracking for immediate performance insights.

Automated inspection for higher accuracy and traceability.

Enhanced part management using QR codes.

Streamlined workflows with less manual intervention.

Improved interdepartmental communication.

Predictive maintenance to reduce downtime.

Data-driven forecasting for better planning.

Optimized operations and sustained competitiveness.

AR/VR Applications

Training

Augmented Reality (AR) and Virtual Reality (VR) have transformed workforce training in sheet metal fabrication. New employees use VR simulations to practice operating machinery in a safe, controlled environment. These immersive experiences build confidence and skills without risking equipment or materials. AR overlays guide technicians through complex assembly or maintenance tasks, reducing errors and speeding up onboarding.

Companies report faster training times and improved retention when using AR/VR tools. Workers gain hands-on experience before stepping onto the production floor.

Design Visualization

Design visualization has reached new heights with AR and VR. Engineers and clients can explore 3D models of sheet metal parts and assemblies in virtual space. This capability allows teams to identify design flaws, test fit and function, and make changes before production begins. AR tools project digital prototypes onto real-world workspaces, helping teams visualize how parts will integrate with existing systems.

These technologies foster better collaboration between design, engineering, and manufacturing teams. Decisions happen faster, and products reach the market sooner. Smart manufacturing, powered by IIoT and AR/VR, sets a new standard for innovation and agility in sheet metal fabrication.

Industry Case Studies

Automotive

Automotive manufacturers rely on sheet metal fabrication for body panels, chassis, engine parts, and interior components. Recent innovations have transformed this sector. Automation, robotics, and advanced CAD/CAM systems now drive production lines. Metal plate bending machines allow engineers to create complex curves and shapes with high precision. These machines reduce production time and labor costs, while improving part consistency and finish. Companies benefit from increased productivity, less material waste, and enhanced safety.

Ford Motor Company uses sheet metal rolling machines to produce aerodynamically optimized hoods, roofs, and fenders. These machines help reduce vehicle weight and improve durability. Precision rolling ensures a perfect fit and finish, which is essential for high-quality vehicles. Automation in bending and rolling processes also supports the use of lightweight and recycled materials, helping manufacturers meet environmental goals. The adoption of AI and machine learning further enhances quality control and efficiency, especially for electric vehicles.

Metal fabrication innovations in the automotive sector lead to faster production, better product quality, and more sustainable vehicles.

Aerospace

Aerospace companies demand high precision and reliability from sheet metal fabrication. Advanced CAD and 3D modeling tools give engineers the flexibility to design complex, customized components. CNC machining and laser cutting technologies ensure accuracy and reduce material waste. Automation and robotics improve safety by limiting human exposure to hazardous tasks and increasing consistency in cutting and welding.

Modern technologies also lower energy consumption and minimize scrap, supporting sustainability goals. Aerospace manufacturers benefit from enhanced durability and strength in their components, which must withstand air pressure and harsh weather. Lightweight sheet metal parts improve fuel economy and aircraft performance. Rapid prototyping with computer-controlled machinery allows for quick production of prototypes or small batches, speeding up development cycles. Companies can customize parts to meet strict industry standards for size, shape, and function.

Automation and robotics speed up cutting, bending, and welding.

3D printing enables rapid prototyping of complex, lightweight parts.

IoT integration provides real-time monitoring and predictive maintenance.

These advancements help aerospace companies reduce costs, improve quality, and support environmental priorities.

SMEs

Small and medium-sized enterprises (SMEs) face unique challenges in adopting new sheet metal fabrication technologies. Many SMEs now use CNC machines, robotic welding, and laser cutting to improve precision and efficiency. Companies like SafanDarley and Durma Machine Tools offer modular, user-friendly machines tailored to SME needs. These solutions help SMEs overcome high capital costs and skilled labor shortages.

Some SMEs use specialized evaluation tools to select the best metal additive manufacturing processes for their needs. This approach helps them balance cost, complexity, and quality. Medium-sized fabricators have integrated automation, such as robotic press brakes and manufacturing execution systems, to streamline production. By reducing work-in-process inventory, these companies free up working capital and improve throughput. Software and automation help SMEs manage complex, flexible production environments, reducing costs and increasing competitiveness.

SMEs that embrace new technologies can compete with larger firms by improving efficiency, product quality, and responsiveness to customer needs.

Future Readiness

Workforce Training

Preparing the workforce for advanced sheet metal fabrication requires a blend of hands-on experience and technical education. Leading training programs combine classroom instruction with extensive lab and on-the-job learning. State-registered apprenticeships, for example, offer a structured pathway:

Aspect | Details |

Program Type | State-Registered Apprenticeship (Sheet Metal Worker, Service Systems Technician) |

Training Duration | 5 years (1,000 hours classroom/lab + 8,000 hours on-the-job) |

Class Size | Cohorts of about 12 students |

Training Focus | Welding, HVAC installation, blueprint reading, fabrication skills |

Certifications | State Certificate, Journey card, eligibility for Associate of Applied Science Degree |

Emphasis | Hands-on skills, weld science, AWS/ASME/API certifications |

Industry-driven academic programs also play a vital role. These programs feature small class sizes and strong employer partnerships. Students spend over 20 hours per week in labs, gaining practical skills in welding, machining, CNC programming, and blueprint reading. Courses such as Mill Applications, Welding Blueprint & Layout, and Sheet Metal Forming & Fabrication build both technical and soft skills, including communication and critical thinking.

Apprenticeships focus on precision metal fabrication and automation.

Training covers CNC programming and industrial maintenance.

Programs support career advancement and certification.

Partnerships with employers ensure training matches industry needs.

This approach ensures employees are ready for the demands of modern fabrication, including robotics and digital manufacturing.

Strategic Investment

Companies that want to lead in sheet metal fabrication must invest strategically. Lean process analysis helps identify inefficiencies and reduce waste, improving both productivity and profitability. Advanced automation technologies, such as CNC press brakes and fiber laser cutting systems, enhance precision and lower operational costs. Data analytics support informed decision-making, allowing managers to optimize production and track performance.

Financial planning remains essential. Companies use detailed capital expenditure strategies and ROI assessments to ensure investments deliver measurable value. Nearshoring and reshoring strengthen supply chains and improve responsiveness to market changes. Empowering employees through automation and ongoing training increases adaptability and productivity. Partnerships with technology providers offer ongoing support, making transitions to new systems smoother and more effective.

Strategic investments in AI, IoT, and automation position companies for scalable growth and long-term competitiveness. These steps help businesses adapt to rapid technological change and seize new market opportunities.

Regulatory Adaptation

Regulatory adaptation shapes the future of sheet metal fabrication. Companies must stay current with evolving safety, environmental, and quality standards. New regulations often require changes in materials, processes, and documentation. For example, stricter emissions rules push manufacturers to adopt energy-efficient equipment and sustainable practices.

Proactive compliance management reduces risk and builds trust with customers and partners. Digital recordkeeping and automated reporting simplify audits and ensure traceability. Many companies now assign dedicated teams to monitor regulatory updates and implement necessary changes quickly.

Staying ahead of regulatory trends not only avoids penalties but also opens doors to new markets and certifications. Companies that prioritize compliance demonstrate leadership and reliability in a competitive industry.

Innovations in sheet metal fabrication now drive remarkable gains in efficiency, sustainability, precision, and competitiveness. Companies accelerate production with automation, robotics, and advanced cutting technologies, while eco-friendly practices and real-time monitoring reduce waste and energy use.

Automation and robotics increase productivity and accuracy by handling repetitive tasks.

3D printing and AR/VR tools support rapid prototyping and efficient design.

Energy-efficient systems and recycling lower environmental impact.

Businesses should invest in workforce training, adopt digital tools, and prioritize sustainable methods. These changes create new opportunities for growth and industry leadership.

FAQ

What are the top innovations in sheet metal fabrication for 2025?

Manufacturers highlight automation, AI-driven quality control, fiber laser cutting, and advanced materials as the most impactful innovations. These technologies improve speed, accuracy, and sustainability across the industry.

How does automation improve safety in sheet metal fabrication?

Robotic systems handle hazardous tasks, reducing workplace injuries. Automated material handling and welding lower the risk of accidents. Workers focus on supervision and quality control, which increases overall safety.

Why is fiber laser cutting preferred over traditional methods?

Fiber laser cutting offers faster speeds, higher precision, and lower maintenance costs. It processes a wide range of metals and thicknesses. Real-time monitoring ensures consistent quality and reduces the need for secondary finishing.

How do companies reduce waste in modern fabrication plants?

Companies use recycling, lean manufacturing, and closed-loop systems. These practices minimize scrap, optimize material use, and support sustainability goals.

What role does AI play in quality control?

AI-powered vision systems detect defects quickly and accurately. These systems analyze production data, predict issues, and help maintain high product standards. Operators use AI insights to make real-time adjustments.

Are small businesses able to adopt advanced fabrication technologies?

Many SMEs now use modular CNC machines, robotic welding, and cloud-based software. These solutions lower entry barriers and help small businesses compete with larger firms.

How do advanced materials benefit the industry?

Lightweight alloys and smart materials increase strength, reduce weight, and improve product performance. These materials support energy efficiency and enable new design possibilities.

What skills do workers need for future sheet metal fabrication jobs?

Workers need experience with CNC programming, robotics, and digital tools. Training programs focus on hands-on skills, technical knowledge, and certifications in welding and fabrication.