Overview

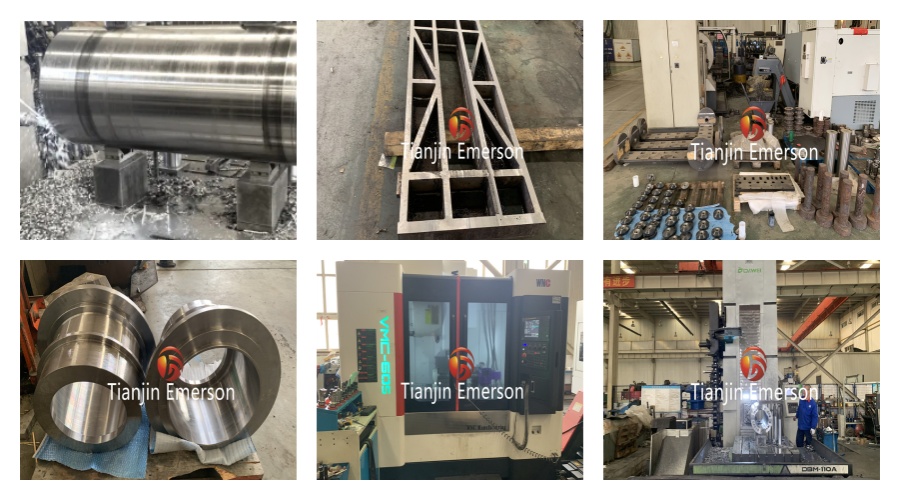

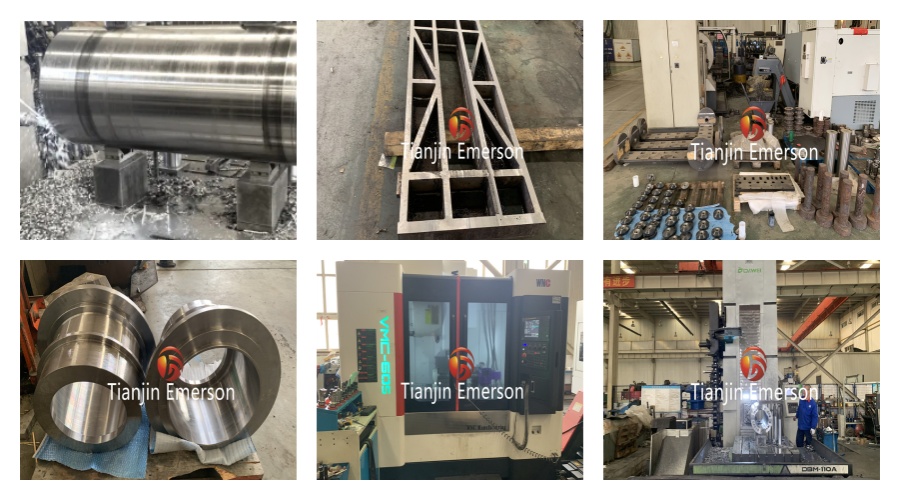

Our High Precision Custom Stainless Steel CNC Milling Metal Parts are engineered for excellence in a wide range of industrial applications. With advanced CNC machining technology and premium-grade stainless steel materials, these parts are designed to meet the most stringent demands for precision, durability, and reliability. They are ideal for use in industries such as automotive, aerospace, electronics, medical devices, and more, ensuring high-performance solutions for complex manufacturing processes.

These CNC-milled metal parts are custom-designed to meet specific customer requirements, offering versatility in both design and application. Our commitment to precision and quality ensures that each part meets rigorous standards, making them ideal for high-demand applications.

Key Features

High-Precision CNC Machining

We use state-of-the-art CNC milling technology to produce parts with intricate designs and tight tolerances. Our equipment provides accuracy down to microns, ensuring that every component is manufactured to exact specifications.

Advanced multi-axis CNC milling capabilities allow us to produce complex parts in various shapes, including precise contours, threads, and slots.

Premium Stainless Steel Materials

We offer parts manufactured from premium stainless steel grades such as 201, 304, 316, and other specialized alloys. Stainless steel is known for its corrosion resistance, high strength, and excellent durability, making it ideal for a range of applications.

We can also provide specific surface treatments, including polishing, anodizing, and passivation, to further enhance the material’s longevity and performance.

Customization Options

Whether you need a single prototype or large-scale production runs, we can tailor the design and specifications to suit your needs. From custom dimensions to unique features, we ensure the parts fit seamlessly into your assembly or system.

We offer a wide range of post-processing options, including drilling, threading, engraving, and finishing, to achieve the final product exactly as required.

Strict Quality Control

Each part undergoes rigorous quality control checks throughout the manufacturing process. From initial design to final inspection, our team ensures that every component meets the highest standards.

Our machining process follows ISO 9001 quality management standards, ensuring consistent quality and reliability for all parts.

Fast Turnaround and Competitive Pricing

With our efficient manufacturing processes, we provide fast turnaround times without compromising on quality. We work closely with you to meet your deadlines, offering rapid prototyping and just-in-time production.

Our competitive pricing ensures that you receive high-quality, custom parts at an affordable rate, helping to optimize your production costs.

Technical Specifications

| Feature | Specification |

| Material | Stainless Steel (304, 316, 201, Custom Alloys) |

| Machining Process | CNC Milling, CNC Turning, Drilling, Threading, Engraving |

| Tolerance | ±0.001mm, High Precision |

| Surface Finish | Polished, Anodized, Passivated, Custom Finishes |

| Applications | Aerospace, Automotive, Electronics, Medical, Industrial |

| Post-Processing Options | Heat Treatment, Surface Coating, Engraving |

| Minimum Order Quantity | Customizable based on requirements |

| Delivery Time | Rapid Prototyping, Short Lead Time |

| Certifications | ISO 9001 Certified, RoHS Compliant |

Applications

Aerospace Components

Stainless steel CNC-milled parts play a crucial role in aerospace applications, where strength, lightweight properties, and resistance to corrosion are vital. These parts are used for producing critical components such as aircraft engine parts, turbine blades, and structural frames for both commercial and military aircraft. Their precision ensures that the components fit seamlessly, ensuring high performance and safety in the demanding aerospace environment.

Automotive Parts

In the automotive industry, precision machining is essential for producing high-performance parts such as engine components, chassis parts, transmission systems, and exhaust components. Our stainless steel CNC milling ensures the highest quality standards for critical automotive parts, delivering strength, durability, and resistance to wear and tear. This is particularly important for performance vehicles, heavy-duty trucks, and electric vehicles where reliability and longevity are paramount.

Medical Devices

Stainless steel is widely used in the medical field due to its biocompatibility, corrosion resistance, and durability. CNC milling of stainless steel is used to create highly precise and reliable components for medical devices, including surgical tools, implants, diagnostic equipment, and prosthetics. Our precise machining capabilities ensure that each part meets stringent medical standards, ensuring both safety and effectiveness in medical applications.

Industrial Equipment

Stainless steel CNC milling is critical in the production of industrial machinery and equipment. From pumps, valves, and pressure vessels to precision tools, our high-precision parts ensure that industrial machinery operates with maximum efficiency. These parts can withstand high pressures, corrosive environments, and extreme temperatures, making them ideal for use in power plants, chemical processing, and other industrial settings.

Electronics

In electronics manufacturing, CNC-milled stainless steel parts are essential for producing high-quality enclosures, connectors, heat sinks, and components that require precision for optimal functionality. These parts must be able to withstand both mechanical stress and electrical conductivity, ensuring reliability and longevity in various consumer electronics, industrial devices, and communication equipment.

Marine Equipment

Stainless steel CNC parts are vital in the marine industry due to their resistance to corrosion in harsh marine environments. These parts are used in the manufacturing of boat components, offshore platforms, and other maritime applications. Components like propellers, hulls, and engines benefit from stainless steel’s strength and resistance to saltwater corrosion, making them perfect for marine equipment.

Energy Sector

In the energy industry, particularly in oil and gas extraction, renewable energy technologies, and power generation, stainless steel CNC milling is essential for creating durable, reliable parts. Components such as turbines, valves, and pipes must withstand high pressures, corrosive chemicals, and extreme temperatures. CNC-milled stainless steel parts help ensure the longevity and efficiency of energy production equipment.

Frequently Asked Questions (FAQ)

What is the difference between CNC milling and traditional machining?

CNC milling uses computer-controlled machines to precisely cut and shape materials, ensuring higher accuracy and repeatability compared to traditional machining. It allows for complex designs and the production of parts with intricate geometries.

What types of stainless steel do you use for CNC machining?

We work with various grades of stainless steel, including 201, 304, and 316. Each type has unique properties such as corrosion resistance and strength, making them suitable for different applications. We can also accommodate custom alloys if required.

What is the lead time for custom CNC milling orders?

Lead times for custom CNC milling orders vary depending on complexity, material availability, and quantity. Typically, we provide rapid prototyping and short lead times, with most projects completed in a few weeks.

Can you handle small-batch production?

Yes, we specialize in both prototype and small-batch production. We offer cost-effective solutions for low-volume orders while maintaining high-quality standards.

Do you offer surface finishing options?

Yes, we offer a variety of surface finishing options including polishing, anodizing, passivation, and custom coatings to meet specific aesthetic and functional requirements.

What is the minimum order quantity (MOQ)?

The MOQ depends on the specific requirements of your project. We can accommodate both small and large production runs, with flexible order sizes based on your needs.

Can you provide design assistance for CNC machining parts?

Yes, we offer design assistance to help optimize parts for CNC machining, ensuring that the design is manufacturable and cost-effective while maintaining the required specifications.

Conclusion

Our High Precision Custom Stainless Steel CNC Milling Metal Parts provide unmatched accuracy, durability, and versatility for a wide range of industrial applications. With advanced machining capabilities, premium materials, and strict quality controls, we ensure that every part meets the highest standards. Contact us today to discuss your custom CNC machining needs and receive a tailored quote.